Product Extraction System

The Product Extraction System is a powerful, industrial-grade solution designed to remove residual liquids or powders from drums and containers prior to or after the wash cycle. Whether you're dealing with viscous materials, chemicals, or solvents, this system ensures that containers are properly emptied—enhancing both the cleaning process and overall operational efficiency.

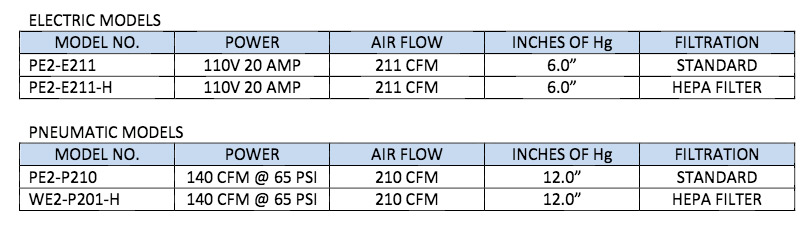

Available in electric and pneumatic models, it generates up to 6 inches of mercury (Hg) for electric units and 12 inches of mercury (Hg) for pneumatic units—delivering strong vacuum force to extract residues thoroughly and reliably.

Why Pre-Extraction Matters

Efficient container washing starts with clean containers. Removing residual materials before washing delivers multiple benefits that improve cleaning quality, reduce downtime, and extend system longevity.

- Prevents premature contamination of the wash fluid

- Speeds up wash/rinse cycles by reducing residue volume

- Decreases frequency of wash fluid replacement or filtration

- Reduces equipment maintenance and sediment buildup

- Standardizes the washing time across containers, ensuring operational consistency

- Enables recovery and reuse of flowable residues—such as paints, oils, fuels, or solvents—helping turn waste into sellable products

Post-Wash Extraction & Drying Efficiency

Residual wash fluids can compromise drying efficiency and cleanliness. The Product Extraction System removes leftover rinse or wash fluid from containers after the cleaning process—especially beneficial when using heated wash systems.

- Ensures complete removal of residual fluids to support fast drying

- Reduces or eliminates the need for costly drying equipment

Available Accessories & Options

- 3-Ring Steel Drum

- Drum Dolly

- In-Line Drum Filter – Protects system from abrasive waste and residues

- 3-Drum Tilt Station

- Upgrade to PE4 Series for enhanced performance

The Product Extraction System helps streamline operations, reduce waste, and improve sustainability—all while ensuring a safer, cleaner, and more consistent container cleaning workflow.

Brochure